This continued commitment, coupled with the fact that the programme’s environmental editorial content is so intrinsically linked to sustainability means they are ahead of many in ensuring their carbon footprint is as low as possible.

The production team had been looking into ways to make 2020 their most sustainable year yet. One of the biggest issues that they had was the generators needed to power rural locations with 100-120 people on site. In order to move away from fossil fuel generated power, the production had been investigating hydrogen generators for their sites, whose only by-product is water and heat.

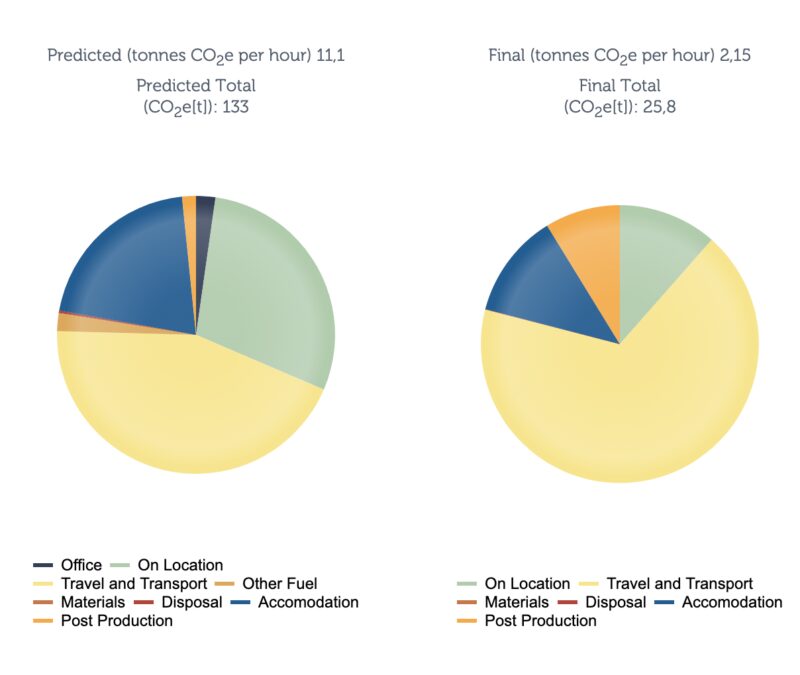

However, with lockdown hitting just as filming was starting, the team had to completely rethink the way they were going to produce the series. With social distancing measures in place, rather than taking big crews to one location, they found the solution was to have smaller crew hubs go out in numbers of 3-6 to around 10 locations, therefore negating the need for huge amounts of power and generators altogether.